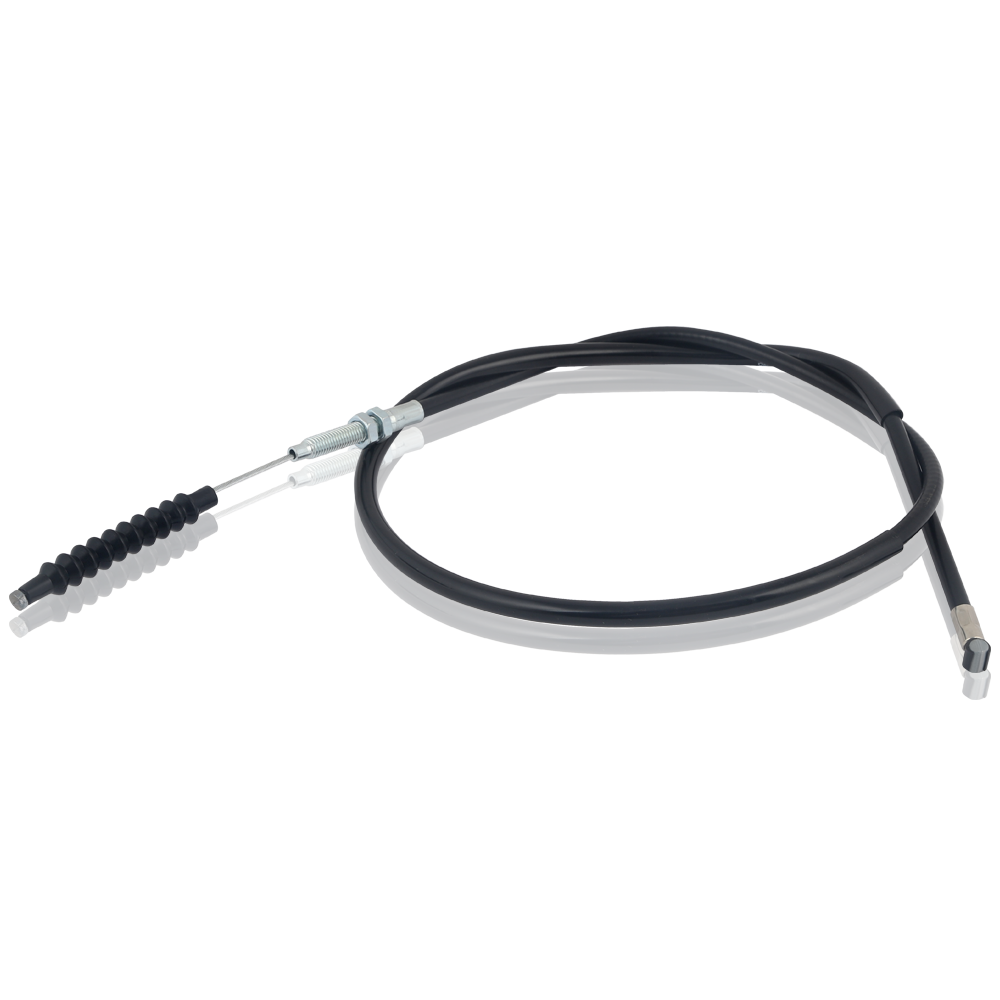

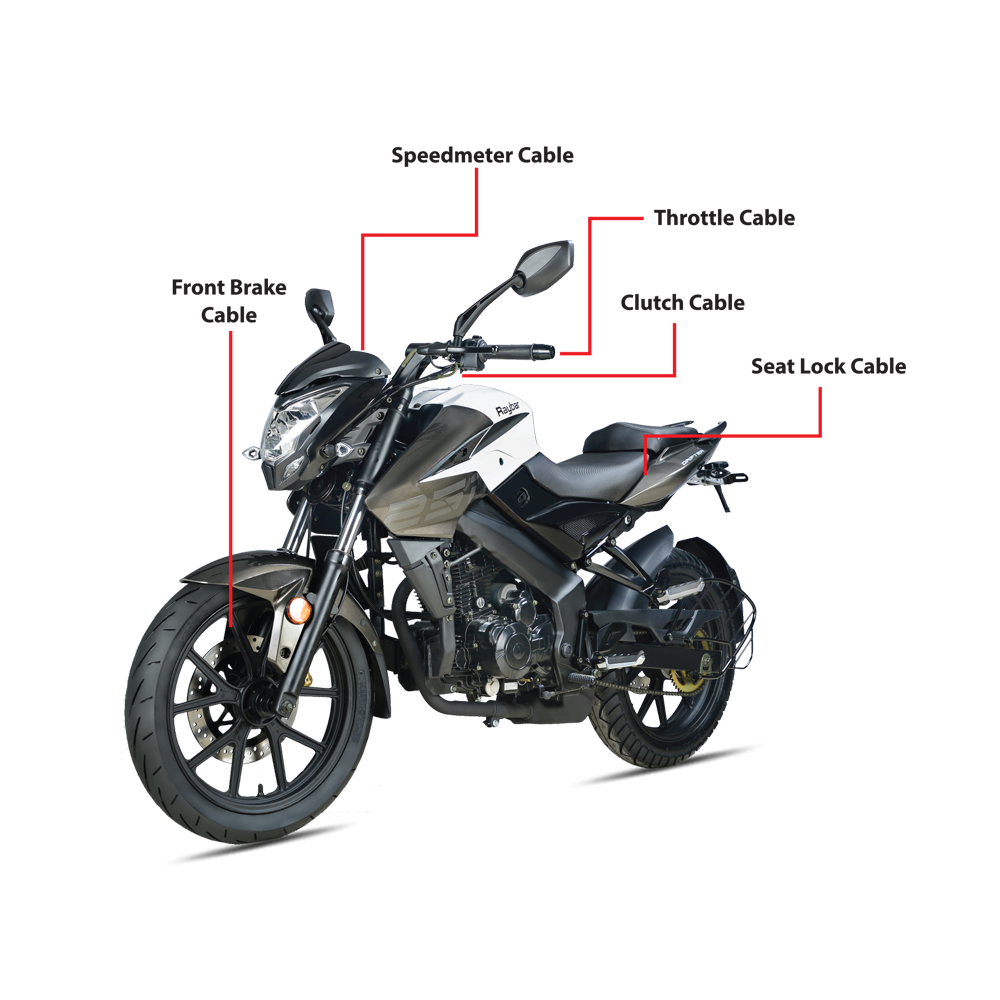

Raw Material

A part from utilization of high quality virgin PVC material, we manufacture our cables with more copper strands to ensure enhanced and improved conductivity. All our products have ISO 9001 certification that augments our reliability factor further.

Our modernized and streamlined production process help us to achieve unparalleled quality that in turn make us the most sought-after brand in spare parts industry.Raw Material strengths: –

Our modernized and streamlined production process help us to achieve unparalleled quality that in turn make us the most sought-after brand in spare parts industry.Raw Material strengths: –

- High quality virgin PVC

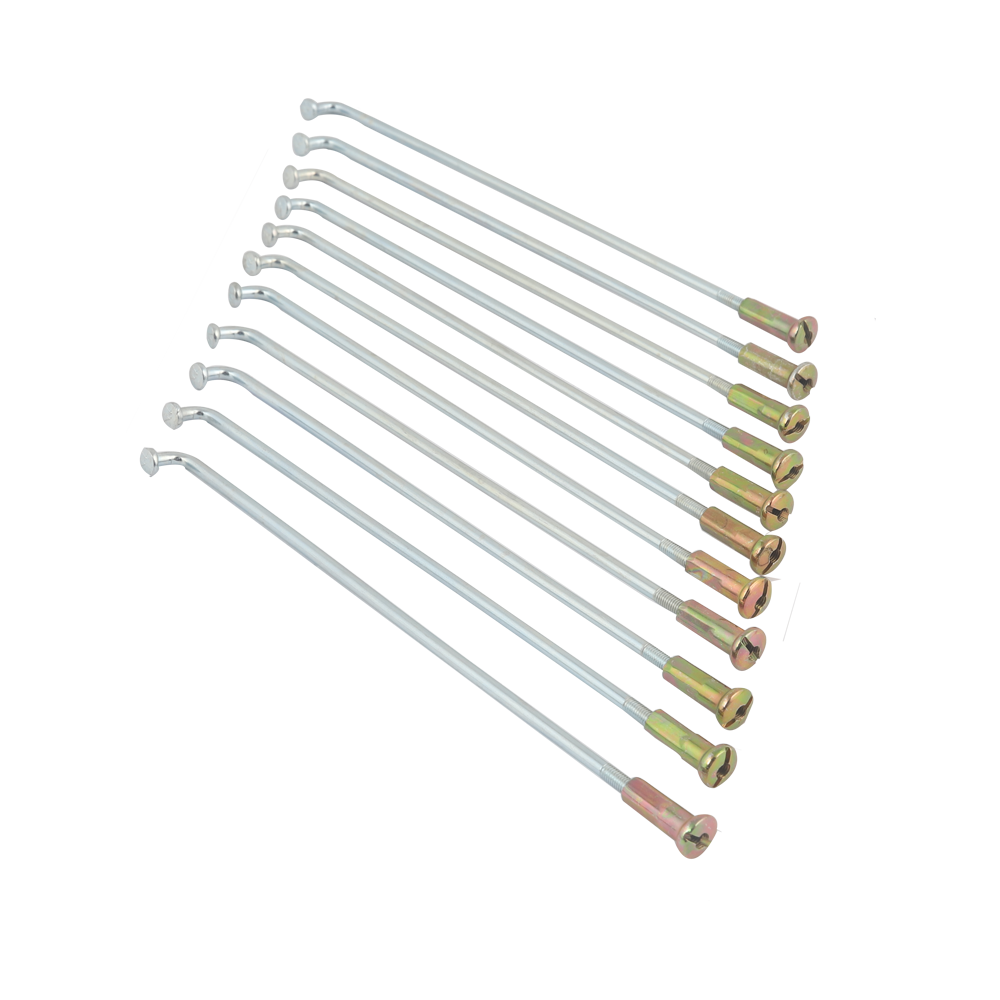

- Copper and zinc plated terminals

| Parameter | Details | RITSUKA | Chinese Product | RITSUKA Advantage |

|---|---|---|---|---|

| BOP(Bought Out Parts) | Inner Cable Wire | Inhouse | BOP | Inhouse Parts Ensures Better Process Control, therefore ensuring better Quality and Delivery |

| Inner PVC Pipe | Inhouse | BOP | ||

| Outer Sleeve Steel Casing | BOP | BOP | ||

| Outer PVC | Inhouse | BOP | ||

| Cable End Attachment | BOP | BOP |