Description

- Number of Teeth is the total count of the number of teeth (projections) around the whole circumference of asprocket. For sprockets with very few teeth it is easy to simply count the number of teeth. However, forsprockets with a higher number of teeth, attempting to count the teeth may not be very practical oraccurate

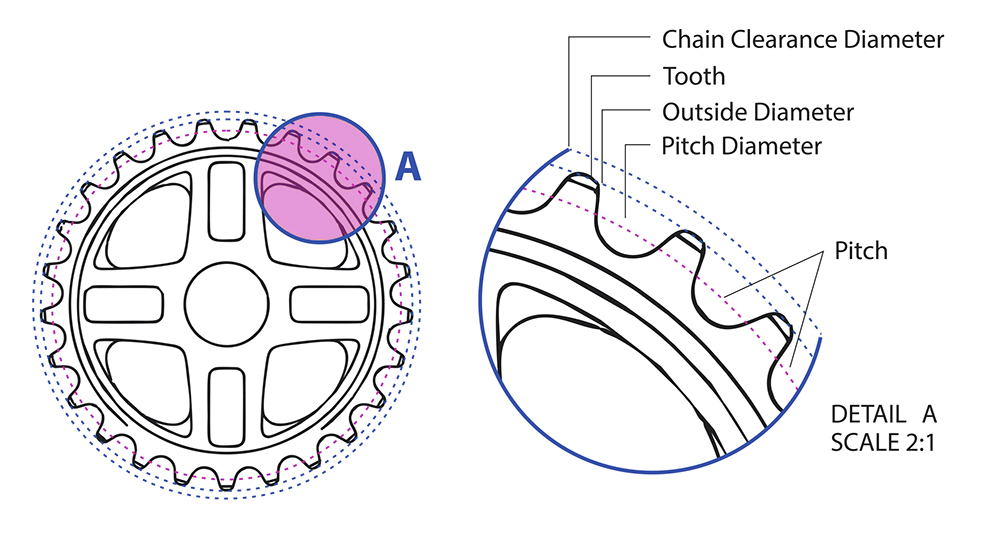

- Pitch Diameter (PD) is an imaginary circle which is traced by the center of the chain pins when the sprocketrotates while meshed with a chain. The ratio of the pitch diameter between sprockets can be used tocalculate the gear ratio, but more commonly and much more simply the ratio of the number of teeth is usedfor this calculation.

- Pitch represents the amount of pitch diameter in inches per tooth. Gears with a larger pitch will have biggerteeth. Common pitches are 0.25”, known as #25, and 0.375” (#35).

- Outside Diameter (OD) will always be larger than the pitch diameter but smaller than the chain clearance diameter. Theoutside diameter does not account for the additional diameter added by the chain, so it should not be used to check forassembly interference.

- Chain Clearance Diameter is the outside diameter of a sprocket with chain wrapped around it. The chain clearancediameter will always be larger than the pitch diameter and the outside diameter. Thechain clearance diameter should beused when checking for interference when placing sprockets very close to other structures.

We at RITSUKA understand the precision and engineering of each spare to its core and our knowledge and focused approachleads us to craft exception sprockets for various models of motorcycle.