Raw Material

We pay special emphasis on raw materials to begin with. As compared to competition we have focused on the smallest part as well. Focus areas when choosing raw materials:

- Light weight and structural material

- Resistant to corrosion

- Endures high temperatures

| Parameter | Details | At RITSUKA | Chinese Product | RITSUKA Advantage |

|---|---|---|---|---|

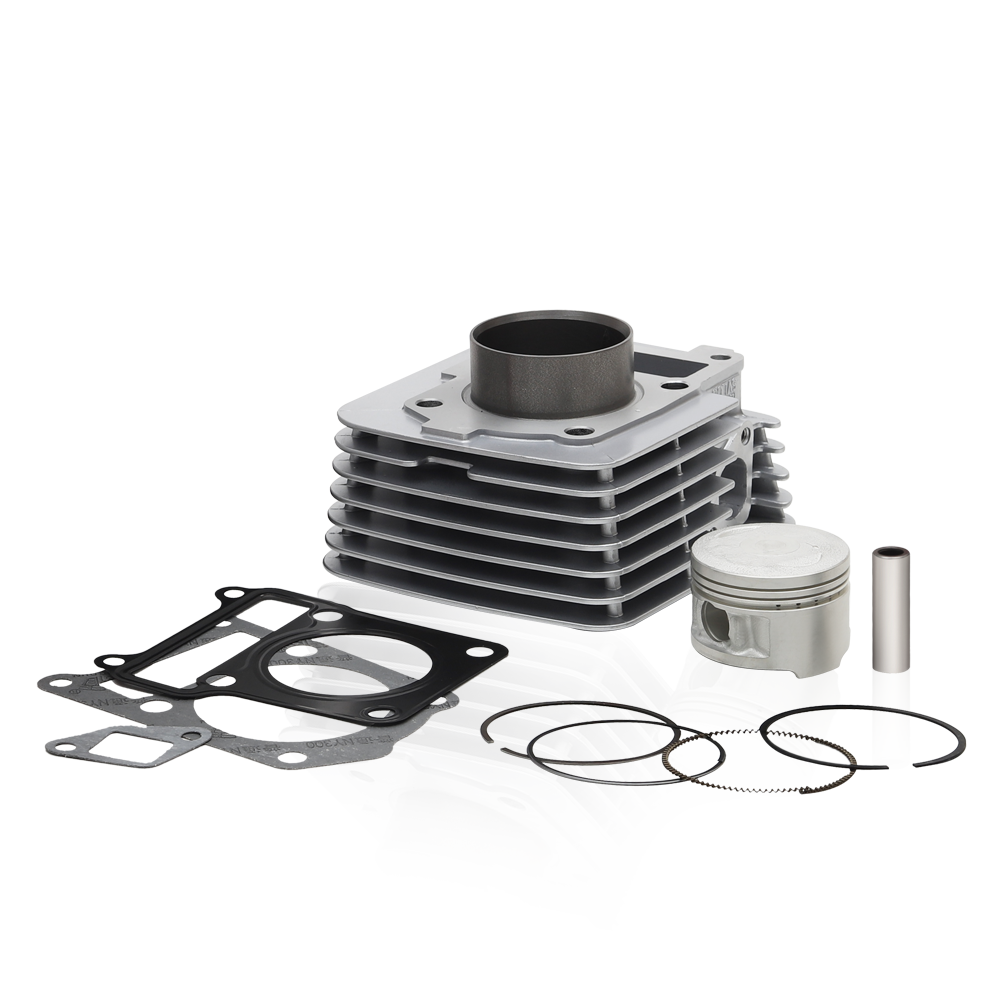

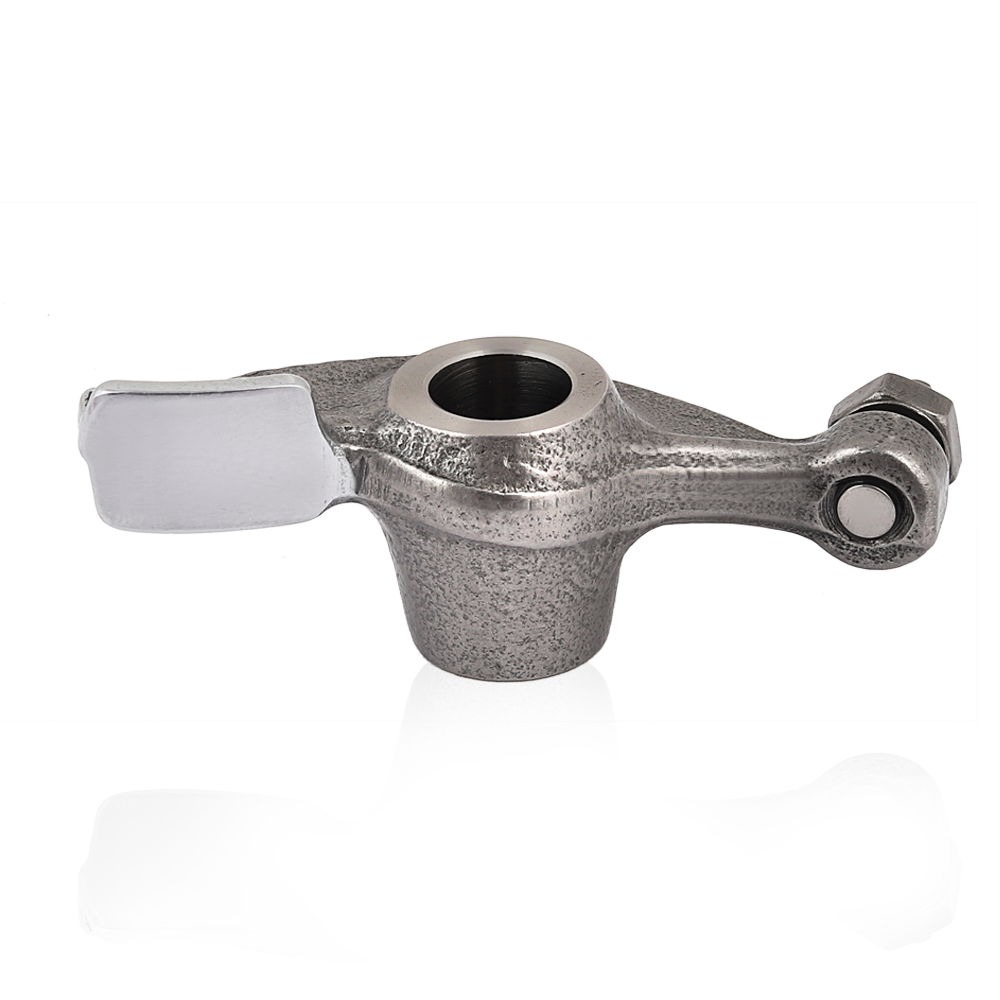

| BOP(Bought Out Parts | Iron Sleeve | Inhouse | BOP | More the BOP’s higher are the chances of rejection |

| Piston Pin | Inhouse | BOP | ||

| Piston | Inhouse | BOP | ||

| C Clips | BOP | BOP | ||

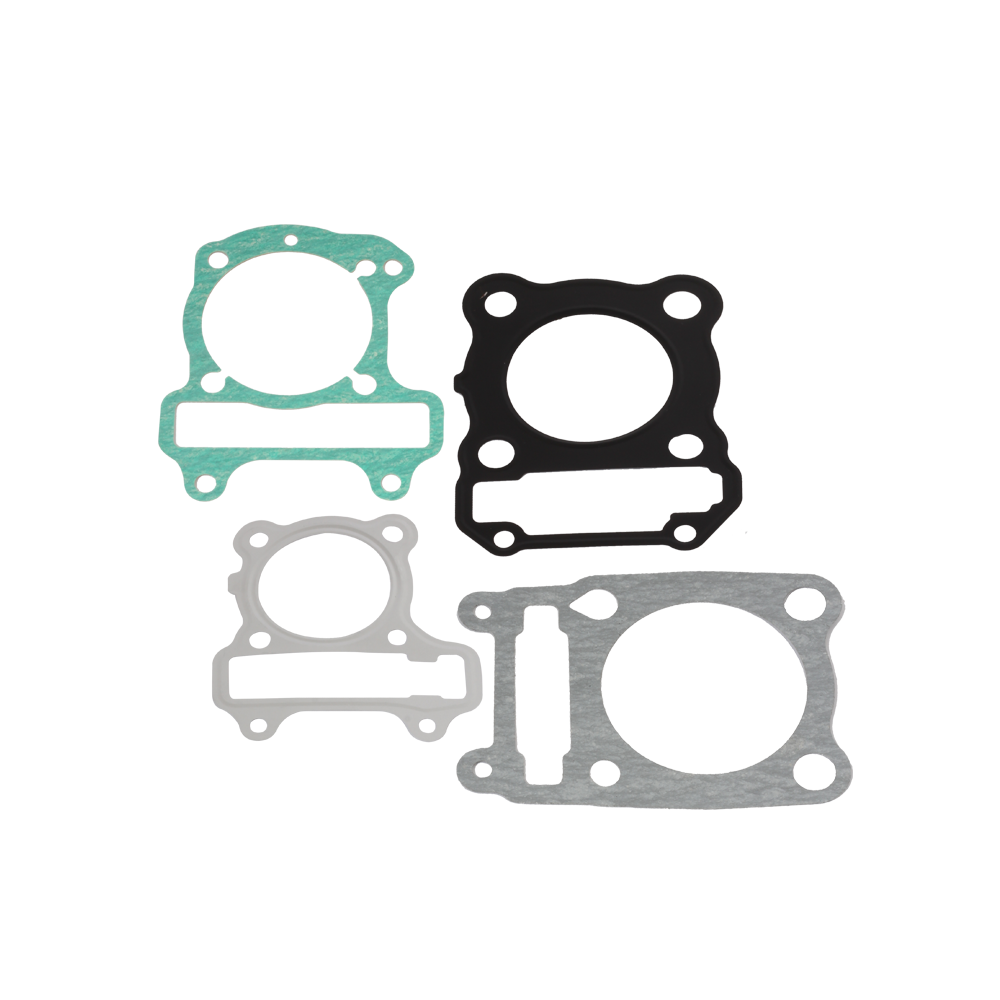

| Gasket | BOP | BOP |

| Parameter | Details | At RITSUKA | Chinese Product | RITSUKA Advantage |

|---|---|---|---|---|

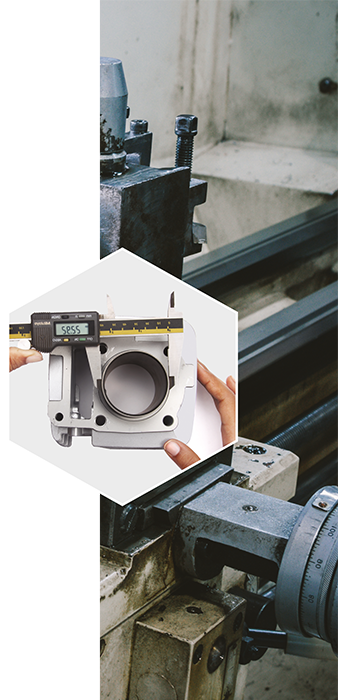

| Raw Material | Cylinder | High grade ADC12 with copper content of 1.65% | Substandard ADC12 with copper content of 0.5-0.8% which is below international standards | High Copper content in Cylinder & Pistons substantial increases in strength and facilitates precipitation hardening |

| Piston | High grade AC8A with copper content of 1.65% | Substandard ADC12 with copper content of 0.5-0.8% which is below international standards | We use raw material composition engineered to reduce ductility and corrosion resistance. More ductility i.e. ? 1% leads to vesatility and higher performance at lower cost | |

| Sleeve | High Grade Cast Iron | Low Grade Cast Iron | Heat treated Corrosion resistant iron grade for robust function and less wear & tear | |

| Rings | High Grade Rings Material – Compression Ring – DH 30 Nodular cast iron 2. Wiper Ring – (DQ20) STEEL 3. Oil Ring – DS45) STEEL | Normal Steel rings | 1. We offer Lightweight & structural material 2. With precise specifications from high grade grey iron castings. Derived from OEM factory – ATG | |

| Piston Pin | High Grade (20CrMo) Steel | Low grade Steel | Our product has high Resistant to corrosion | |

| Gasket | Fresh Rubber (NBR) | Recycled Rubber | Seal proof operation without any power loss |