Raw Material

Our levers are made of high quality ZL104 and 4 Grade Plating Finish. This material has high copper percentage thatmeans you get to ride with exceptional durability, betterperformance and longevity. ZL104 increases the resistance of a material to breaking under tension or load. It also improves tensile strength of a material and enables it to bear maximum amount of tensile stress before giving up to failure i.e. breaking. Wrought aluminum-copper alloys respond to solution heat treatment and subsequent aging with an increase in strength and hardness and a decrease in elongation. Aluminium alloys offers.

Why these raw materials were chosen?

- Lightweight

- Resistant to Corrosion

- Endurance high Temperatures

| S.no. |

Parameter |

Details |

RITSUKA |

Chinese Product |

RITSUKA Advantage |

| 1 |

BOP |

Paint |

Outsourced |

Outsourced |

Outsourced from standard paint manufacturers |

| 2 |

Raw material |

Aluminium alloy ZL-104 |

High grade ZL-104 aluminium ingots |

Substandard ZL-104 |

1) Excellent castability |

Chemical composition

| S.No. |

Component |

% age |

| 1 |

Cu |

0.2 |

| 2 |

Fe |

0.6 |

| 3 |

Zn |

0.1 |

| 4 |

Ti |

0.2 |

| 5 |

Mg |

0.2~0.6 |

| 6 |

Mn |

0.3~0.7 |

| 7 |

Pb |

0.1 max. |

| 8 |

Si |

10~13 |

| 9 |

Ni |

0.1 max. |

| 10 |

Sn |

0.05 max. |

| 11 |

Al |

Balance |

| 12 |

others |

0.05 max |

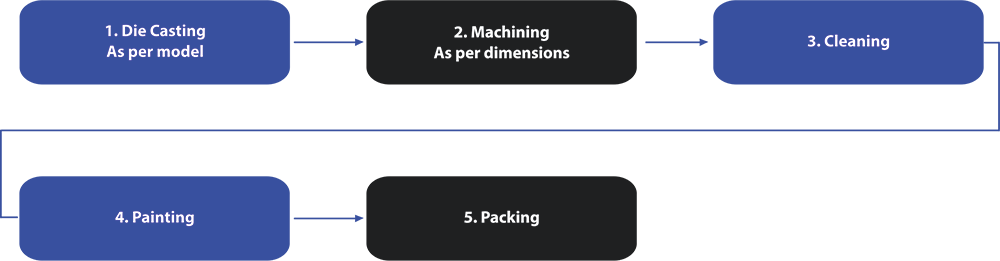

Manufacturing

All our product manufacturing is done as per GB standards. Here’s a comparison of our product from the Chinese product.

| S.no. |

Parameter |

Details |

RITSUKA |

Chinese Product |

RITSUKA Advantage |

| 1 |

Manufacturing as per GB standard |

Die casting |

Inhouse aluminium die casting |

Outsourced |

Inhouse manufacturing ensures better quality control on produced parts |

| Machining |

Inhouse |

Outsourced |

Inhouse manufacturing ensures better quality control on produced parts |

| Painting |

Inhouse |

Outsourced |

Inhouse manufacturing ensures better quality control on produced parts |

Testing

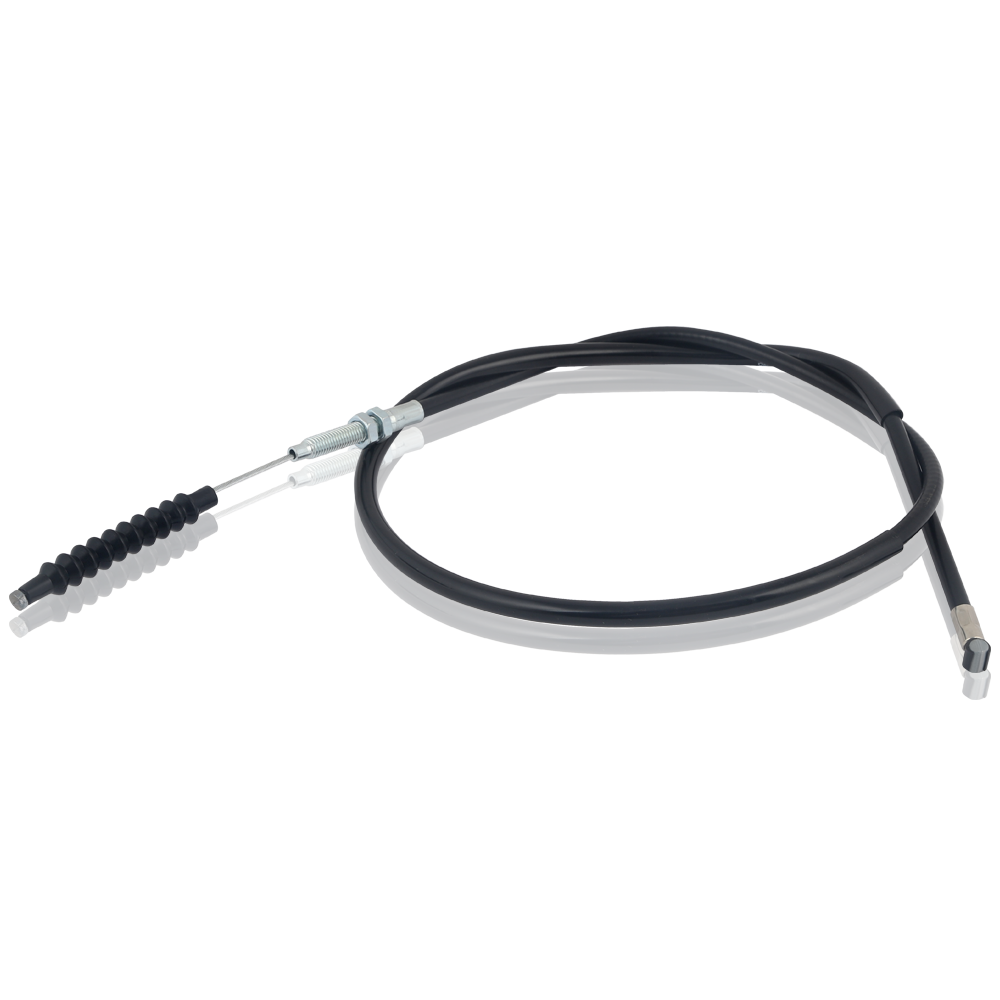

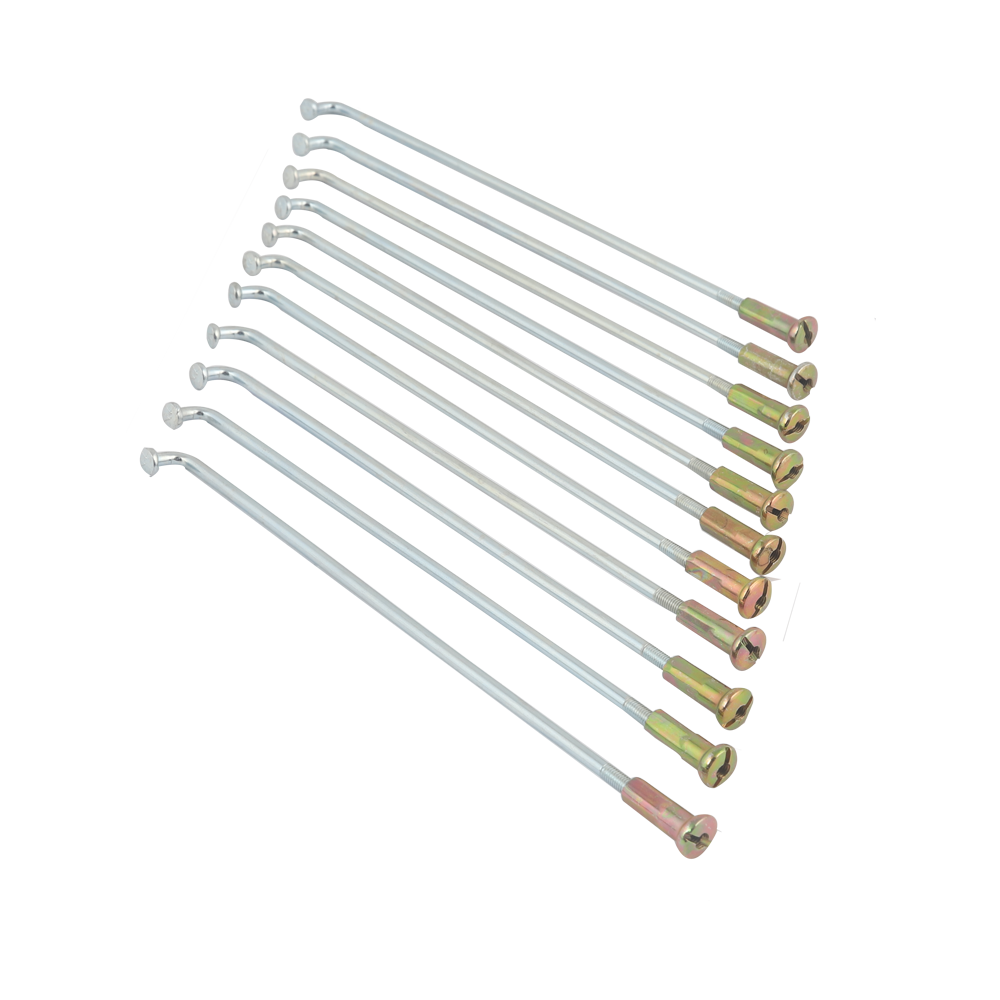

We have a dedicated product quality team who takes care of all the testing of the product and raw material at the pre and final stage. Each of our spokes is further tested on international standards.

| S.no. |

Parameter |

Details |

RITSUKA |

Chinese Product |

RITSUKA Advantage |

| 1 |

Testing Standard |

Incoming Quality Inspection |

100% inspection of incoming raw material |

No testing |

This ensures that incoming parts are within tolerance limit |

| In process |

100% quality check at different processes to check the dimension and shape |

No quality check, since it requires extra manpower/extra cost |

This ensure the produced parts is within tolerance limit |

| Final inspection |

All the products are checked before dispatch to ensure good quality |

No quality check, since it requires extra manpower/extra cost |

Defect free product to customer. |

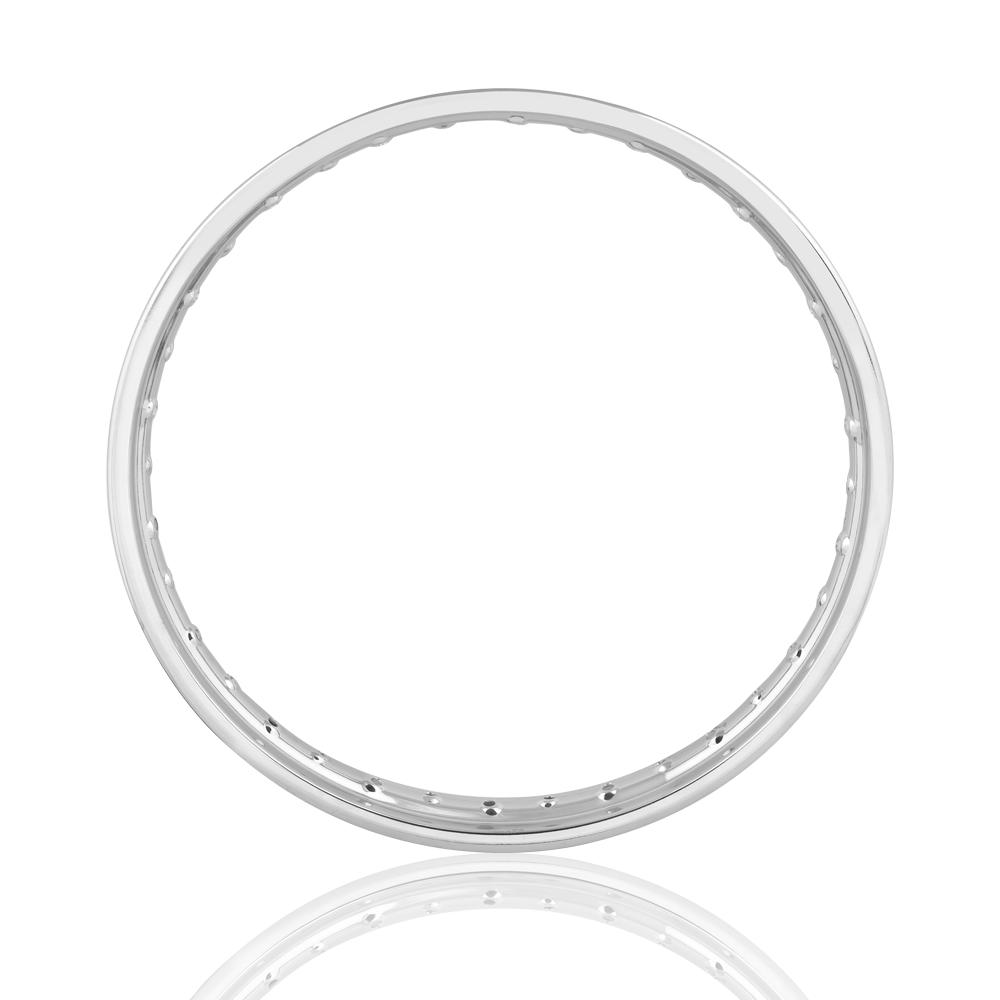

Material Composition Test

Spectrograph is used to check the material composition of the die casting part.

| S.no |

Parameter |

Details |

RITSUKA |

Chinese Product |

RITSUKA Advantage |

| 1 |

Testing Standard |

Material composition test |

Testing though spectrograph |

No testing |

All the tests are performed as per GB standard to ensure defect free product |