RAW MATERIAL

We use lining without asbestos as they are environment friendly and it has an ability to operate in all conditions at constant wear rate. For Brake Shoe, we use ADC 12 that has high copper percentage of 1.65% that means exceptional mechanical properties like durability, comfort and longevity for your motorcycle in simple words.

ADC 12 increases the resistance of a material to breaking under tension or load. It also improves tensile strength of a material and enables it to bear maximum amount of tensile stress before giving up to failure i.e. breaking.

We trust aluminum alloys because:

- Lightweight & structural material

- Resistant to corrosion

- Endures high temperatures

| Parameter |

Details |

RITSUKA |

Chinese Product |

RITSUKA Advantage |

| Raw Material |

Aluminium Body |

High grade ADC12 with copper content of 1.65% |

Substandard ADC12 with copper content of 0.5-0.8% which is below international standards |

We offer ECE-R90 certified formulation with High Copper content means exceptional mechanical properties like durability, comfort and longevity along with safe ride. |

| Lining |

Non-Asbestos formation with special Fiber material |

With Asbestos formation |

We offer Environment friendly Non-asbestos friction material as Asbestos material has been banned in most of the countries. Results in smooth braking effect |

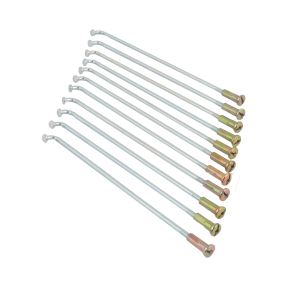

| Spring |

Spring Material 65# Mn Steel |

Low Grade Steel |

- Robust function and less wear & tear

- Durable standards

- Corrosion resistant finish

|

| Parameter |

Details |

RITSUKA |

Chinese Product |

RITSUKA Advantage |

| BOP (Bought Out Parts) |

Brake Lining |

Inhouse |

BOP |

- More the BOP’s higher are the chances of Rejection.

- Consistent Quality and best performance in service life

|

| Spring |

BOP |

BOP |

Manufacturing

Our manufacturing facilities are what give us edge over other Chinese products. With fully automated line with minimal manual intervention, we are the top manufacturers of these products.

| Parameter |

Details |

RITSUKA |

Chinese Product |

RITSUKA Advantage |

| Manufacturing |

Production Technology |

Automated Casting machines |

Semi-Automated Casting machines |

By using fully automated CNC machines, We offer min. tolerance level products with negligible |

| Design center, Tool room and R&D |

Inhouse Design center, tool room |

Not available with normal Chinese |

We have an extra ordinary aptitude in developing customized formulations for friction products. For die casted products, the company has in-house tool room with integrated facilities for die design & die manufacturing enabling quick lead time to customers. |

| Gluing process |

Automated gluing process |

Manual gluing process |

Proper gluing results in better shear strength and Brake grip |

| Sandblasting |

Inhouse facility |

Not available |

We offer sandblast Brake shoe with smoother surface finish and edges as compared to other brake shoe in the market |

| Heat Treatment |

Inhouse Heat treatment process |

Outsourced in most of the factories |

Grain alignment to give better raw material strength and to reduce internal stress |

Testing

During new product development, each product undergoes complete physical & chemical properties testing before going for functional and endurance testing. The finished brake shoes are made to undergo various checks and tests to ensure precision and quality is attained at every level, in best way possible. For your trust and safety, we always go an extra mile and recheck our passion. Each of the brake shoe is evaluated on following parameters, before they make way to market and to you.

| Parameter |

Details |

RITSUKA |

Chinese Product |

RITSUKA Advantage |

| Testing Standards |

Incoming Parts |

100% Inspection & Testing |

Random / No Testing |

Committed to offer same quality / specifications product with every lot |

| In Process |

Inhouse facility includes

- Material composition test

- Random Dimensional check with Three axis coordinate measuring machine

- Coefficient of Friction test

- Shear Strength Test

- Crushing Strength Test

|

- Visual testing

- On demand testing from external agencies

|

- Controlled Standard Parameters at every Process

- Product has crushing strength of <13.23KN.

- Through three axis coordinate measuring machine, we maintain 0.003mm ~ 0.003mm tolerance range

- Product has shear strength of <11.20KN

|

| Final Inspection |

Fitment check using pneumatic gauge, Hydraulic / Electronic Universal testing |

Manual inspection |

Ensures safe operation and adequate durability We have both Electronic and Hydraulic universal testing machine(UTM) for testing the tensile strength and compressive strength of materials used in manufacturing |

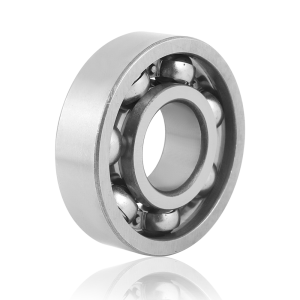

Vibration Test

This test is performed to check the vibration in the bearing

| S.no. |

Test items and Specifications |

Unit |

Chinese Product |

Our Product |

| 1 |

Crushing Strength Test |

kN |

11.89 |

13.23 |

| 2 |

Shear Strength Test |

kN |

10.77 |

10.23 |

| 3 |

Shear Strength |

MPa |

4.10 |

3.8 |

Roundness Testing

This test is performed to check the dimensions of bearing.

| S.no. |

Chemical Composition |

STD |

Chinese Product |

Our Product |

| 1 |

Cu |

1.5˜3.5 |

0.81 |

1.60 |

| 2 |

Mg |

=0.3 |

0.72 |

0.19 |

| 3 |

Zn |

=0.1 |

1.51 |

0.94 |

| 4 |

Si |

9.6˜12 |

10.89 |

10.73 |

| 5 |

Fe |

=1.3 |

1.20 |

0.77 |

| 6 |

Mn |

=0.5 |

0.47 |

0.17 |

| 7 |

Sn |

=0.2 |

0.02 |

0.02 |

| 8 |

Ni |

=0.5 |

0.02 |

0.05 |

| 9 |

Pb |

=0.2 |

0.06 |

0.05 |

| 10 |

Ti |

=0.3 |

0.03 |

0.03 |