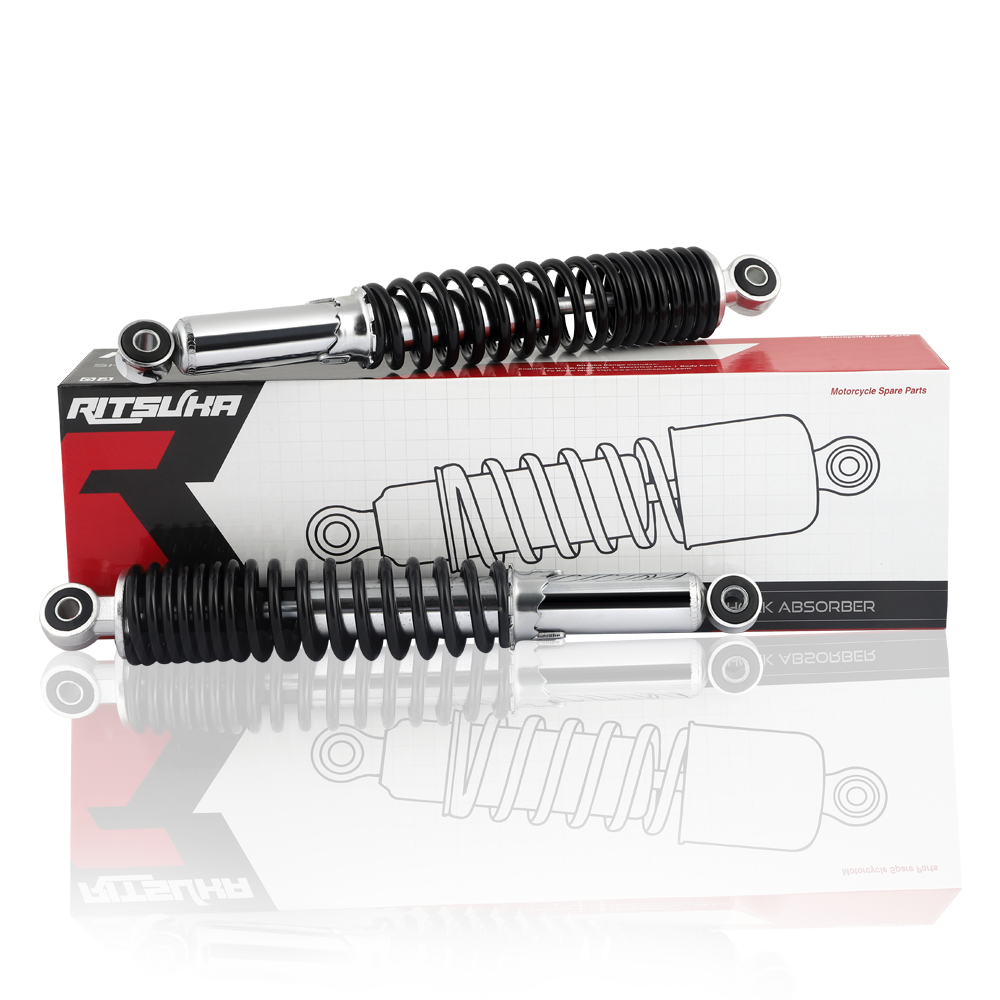

Raw Material

We owe our superiority to the SGS approved factories where products derive their

perfection using innumerable quality parameters. We use minimum BOP (Bought out Parts) to have a complete control of quality.

| Parameter |

Details |

RITSUKA |

Chinese Product |

RITSUKA Advantage |

| BOP(Bought Out Parts) |

Upper Bracket |

BOP |

BOP |

Inhouse Parts Ensures Better Process Control, therefore ensuring better Quality and Delivery |

| Lower Bracket |

BOP |

BOP |

| Spring |

Inhouse |

BOP |

| Internal Tube |

Inhouse |

BOP |

| Inner Piston |

Inhouse |

BOP |

Manufacturing

Our manufacturing facilities are what give us edge over other Chinese products. With fully automated line with minimal manual intervention, we are the top manufacturers of shock absorbers. The core part of shock absorber i.e. spring is also manufactured in-house to control the quality at every point of time.

| Details |

RITSUKA |

Chinese Product |

RITSUKA Advantage |

| Automated line |

Fully Automated Line |

Semi-Automatic or Manual Line |

By using fully automated Line, we offer min. Tolerance level with negligible rejection at final stage |

| Spring Manufacturing |

Inhouse |

Outsourced |

Inhouse Manufacturing Enhances Better Production Control |

| Oil Filling |

Oil Filling through Automated Oil Filling Machine |

Oil Filling is Manual |

Standard Filling Ensures Consistent Damping Feel and no Spilling |

| Electroplating |

100% Plating by Automated Plant |

Semi-Automatic or Manual Facility |

Minimal chances of Inhouse Rejection levels prefinished / finished product |

Testing

Cavitation Test:

Cavitation is presence of air or other contaminated particles inside the shock absorber. Presence of air results in more friction between the cylinder piston and the cylinder wall. In this test, the temperature is kept 20 C and velocity is permitted ±5% and the cavitation is checked at different cycles – 5,100,200,300,400, 500

| Temperature |

20 ± 3 |

°C |

|

Velocity |

0.523 |

m/s |

50 |

mm |

| Cycle |

Specification |

Found |

Visual

(graphic) |

Sample # 1

(OK or NOK) |

Sample # 2

(OK or NOK) |

Sample # 3

(OK or NOK) |

Status

(OK or NOK) |

| 5th |

The hydraulic lag shall not be higher than 50% of stroke test. |

OK |

OK |

OK |

OK |

| 100th |

OK |

OK |

OK |

OK |

| 200th |

OK |

OK |

OK |

OK |

| 300th |

OK |

OK |

OK |

OK |

| 400th |

OK |

OK |

OK |

OK |

| 500th |

OK |

OK |

OK |

OK |

Damping Test

In this test, the internal forces of a shock absorber are measured using hydraulics in motion. Load, displacement, and velocity measurements are recorded to create hysteresis curves to accurately display the affects frequency, displacement, and temperature have on a shock absorber. Test samples can be soaked at temperature and humidity prior to cycling, or the test can be performed in an environmental chamber. If the damping force graph is symmetrical about the origin, then means damping and compression are same, and the shocker is OK.

Friction Force Test

Friction force is the sum of unwanted forces in shock absorber. These forces include forces between the oil andthe contaminated particles, viscous forces in the oil, piston and cylinder wall force. Lesser are the friction forces; better is the quality of the shocker. Practically there cannot be zero friction at all.

| Temperature |

20 ± 3 |

°C |

|

Velocity |

0.002 |

m/s |

50 |

mm |

| Cycle |

Specification |

Found |

| Force (Fat) |

Unit |

Tolerance |

Sample # 1 |

Sample # 2 |

Sample # 3 |

Min |

Max |

Status |

| – |

+ |

| 4th |

0.00 |

kN |

0.00 |

70.00 |

23.00 |

21.00 |

20.00 |

20.00 |

37.00 |

OK |

Corrosion test

In this Test, the shock absorber parts are kept under the controlled environmental conditions for different hours as per Material

- Ni-Cr = 16 Hours

- Zn = 48 Hours

- Hard Cr = 24 Hours

- Painting = 48 Hours

| Item |

Specification |

Found |

| Duration |

Unit |

Tolerance |

Sample # 1

(OK or NOK) |

Sample # 2

(OK or NOK) |

Sample # 3

(OK or NOK) |

Status

(OK or NOK) |

| – |

+ |

Ni-Cr

(CASS) |

16 |

h |

0 |

0 |

OK |

OK |

OK |

OK |

Zi

(NSS) |

48 |

h |

0 |

0 |

OK |

OK |

OK |

OK |

Hard Cr

(NSS) |

24 |

h |

0 |

0 |

OK |

OK |

OK |

OK |

Painting

(NSS) |

48 |

h |

0 |

0 |

OK |

OK |

OK |

OK |

Rubber Bush Testing

In this the rubber bushes are checked visually after 2,00,000 cycles of shocker movement.

| Temperature |

|

20 ± 3 |

°C |

|

Velocity |

0.523 |

m/s |

Stroke |

50 |

mm |

| Cycle |

Specification |

Found |

| Visual |

Tolerance |

Sample # 1

(OK or NOK) |

Sample # 2

(OK or NOK) |

Sample # 3

(OK or NOK) |

Sample # 4

(OK or NOK) |

Status

(OK or NOK) |

| – |

+ |

| 200,000th |

No deformations and cracks |

|

|

OK |

OK |

OK |

OK |

OK |

Dimensional Test

In this test around 15-20 dimensions are checked after final assembly of the shock absorber as per the drawing. Instruments that are used are:

- Ruler

- Vernier Caliper

- Spring Gauge

| Item |

Specification |

Found |

| Dimension |

Unit |

Tolerance |

Sample # 1 |

Sample # 2 |

Min |

Max |

Status |

| – |

+ |

| 1 |

21.00 |

mm |

0.20 |

0.20 |

21.20 |

21.16 |

21.16 |

21.20 |

OK |

| 2 |

14.50 |

mm |

0.20 |

0.20 |

14.70 |

14.66 |

14.66 |

14.70 |

OK |

| 3 |

32.00 |

mm |

1.00 |

1.00 |

31.90 |

31.80 |

31.80 |

31.90 |

OK |

| 4 |

7.20 |

mm |

0.10 |

0.20 |

7.40 |

7.30 |

7.30 |

7.40 |

OK |

| 5 |

28.00 |

mm |

0.20 |

0.20 |

28.00 |

27.93 |

27.93 |

28.00 |

OK |

| 6 |

12.10 |

mm |

0.00 |

0.20 |

12.24 |

12.20 |

12.20 |

12.24 |

OK |

| 7 |

88.00 |

mm |

1.00 |

1.00 |

87.20 |

87.00 |

87.00 |

87.20 |

OK |

| 8 |

21.00 |

mm |

0.20 |

0.00 |

20.86 |

20.90 |

20.86 |

20.90 |

OK |

| 9 |

343.00 |

mm |

3.00 |

3.00 |

344.00 |

343.00 |

343.00 |

344.00 |

OK |

| 10 |

273.00 |

mm |

3.00 |

3.00 |

274.00 |

273.00 |

273.00 |

274.00 |

OK |

| 11 |

18.00 |

mm |

0.00 |

0.25 |

18.20 |

18.23 |

18.20 |

18.23 |

OK |

| 12 |

70.00 |

mm |

Ref |

Ref |

70.00 |

70.00 |

70.00 |

70.00 |

OK |

| 13 |

10.00 |

mm |

0.05 |

0.05 |

9.97 |

9.97 |

9.97 |

9.97 |

OK |

| 14 |

50.60 |

mm |

0.10 |

0.35 |

50.88 |

50.94 |

50.88 |

50.94 |

OK |

| 15 |

208.50 |

mm |

5.00 |

5.00 |

206.50 |

206.90 |

206.50 |

206.90 |

OK |

| 16 |

45.00 |

mm |

2.00 |

2.00 |

45.00 |

45.00 |

45.00 |

45.00 |

OK |

| 17 |

35.00 |

mm |

2.00 |

2.00 |

35.00 |

35.00 |

35.00 |

35.00 |

OK |

| 18 |

6.00 |

mm |

1.00 |

1.00 |

6.00 |

6.00 |

6.00 |

6.00 |

OK |

| 19 |

4.50 |

mm |

1.00 |

1.00 |

4.50 |

4.50 |

4.50 |

4.50 |

OK |