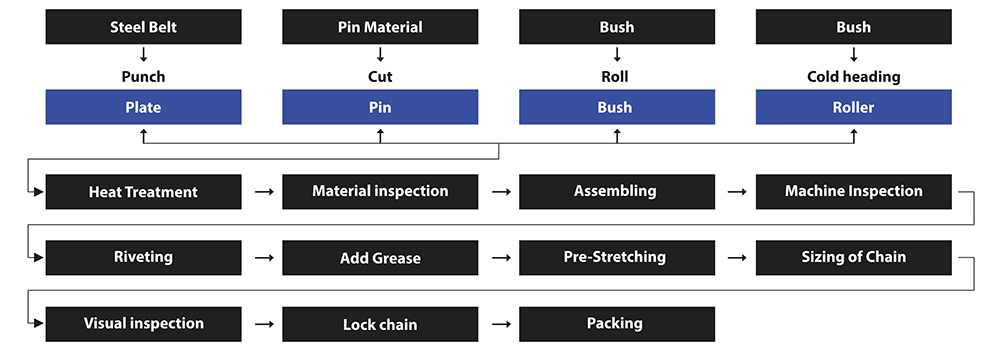

Manufacturing

We follow a precision-based production process wherein quality is imbibed at every step. Our Quality Consistency Control ensures thatbenchmarks are met at every step of the flow and the product reaching a motorcycle user is nothing less than perfection.

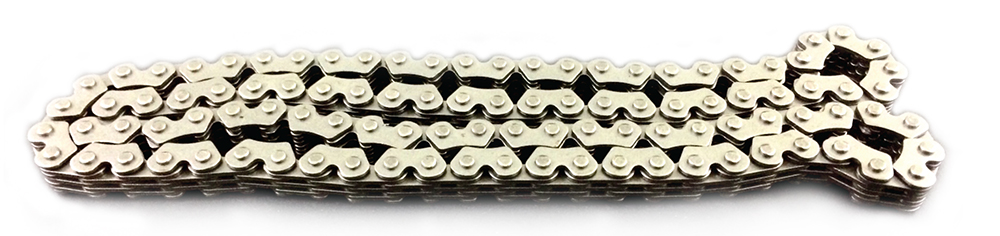

We also manufacture seal-ring Chain that is superior to the competitors’ spare parts. During manufacturing of seal-ring chain, we position a rubberseal ringbetween the inner and the outer plate of the roller chain, which keeps the dust particles out and prevents the grease from flowing out.The

end benefits of such remarkable process are less elongation, silent operation, long life-span and lowlubrication frequency.

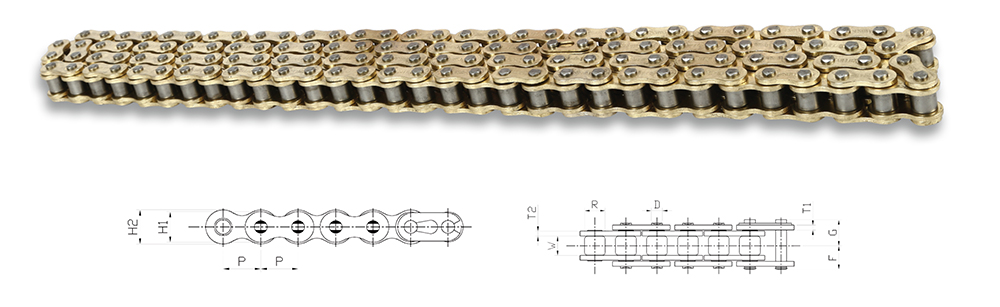

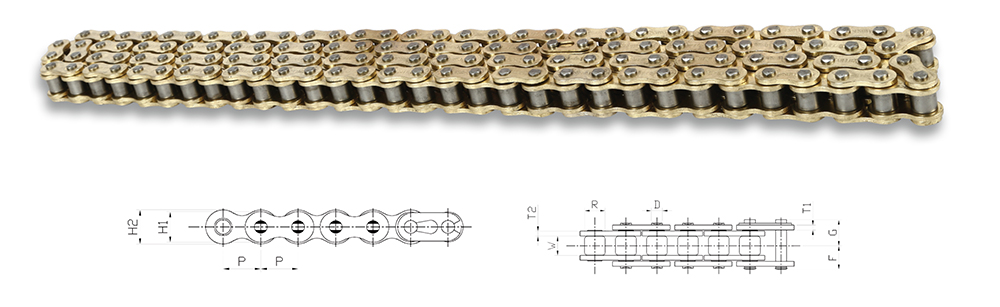

Characteristics of RITSUKA Chain / Seal Chain-Ring

Between the inner and outer plate of the roller chain there is a rubber sealing ring, which keeps out thedust particles and stops the grease from flowing out. This way we do not have tore-grease the chain again. So, the advantage of the seal ring chain is less elongation, silent operation, long service life and lower frequency of lubrication.

| Chain | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| RITSUKA | Pitch | Bush Type | Width | Pin | Roller | Plate Thickness | Tensile | Application | Application by cc | ||

| Chain No. | Dia | Length | Dia | Inner | Outer | Strength | |||||

| mm | mm | mm | mm | mm | mm | mm | KN | ||||

| 415H | 12.700 | Curled | 4.80 | 3.96 | 14.75 | 7.77 | 1.5 | 1.5 | 16.0 | Moped | 50-85 |

| 420H | 12.700 | Curled | 6.35 | 3.96 | 16.60 | 8.15 | 1.8 | 1.8 | 17.0 | Moped | 50-85 |

| 428H | 12.700 | Curled | 7.85 | 4.45 | 18.40 | 10.16 | 2.0 | 2.0 | 20.6 | Street | 125-250 |

| 520H | 15.875 | Curled | 6.35 | 5.08 | 18.80 | 10.16 | 2.42 | 2.42 | 30 | Street | 125-250 |

| 525H | 15.875 | Curled | 7.95 | 5.08 | 22.90 | 10.16 | 2.42 | 2.42 | 30 | Street | 125-250 |

| 530H | 15.875 | Curled | 9.40 | 5.08 | 22.10 | 11.91 | 2.42 | 2.42 | 30 | Street | 125-250 |

| O-Ring | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| RITSUKA | Pitch | Bush Type | Width | Pin | Roller | Plate Thickness | Tensile | Application | Application by cc | ||

| Chain No. | Dia | Length | Dia | Inner | Outer | Strength | |||||

| mm | mm | mm | mm | mm | mm | mm | mm | ||||

| 428HO | 12.700 | Solid | 7.85 | 4.46 | 21.80 | 8.51 | 2.0 | 2.0 | 22.0 | Street/Of-road | 125-200 |

| 5200 | 15.875 | Solid | 6.35 | 5.24 | 20.15 | 10.16 | 2.0 | 2.0 | 26.5 | Street/Of-road/Sports | 150-200 |

| 5300 | 15.875 | Solid | 9.40 | 5.25 | 23.40 | 10.16 | 2.0 | 2.0 | 26.5 | Street/Of-road/Sports | 150-200 |

| 520HO | 15.875 | Solid | 6.35 | 5.26 | 22.00 | 10.16 | 2.42 | 2.42 | 33.0 | Street/Of-road/Sports | 200-350 |

| 525HO | 15.875 | Solid | 7.95 | 5.27 | 23.50 | 10.16 | 2.42 | 2.42 | 33.0 | Street/Of-road/Sports | 200-350 |

| 530HO | 15.875 | Solid | 9.40 | 5.28 | 24.95 | 10.16 | 2.42 | 2.42 | 33.0 | Street/Of-road/Sports | 200-350 |

| Bush Chain | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| RITSUKA | Pitch | Bush diameter | With between inner plates b1 min | Pin diameter | Plate depth | Pin length | Tensile strength | weight per meter | |||

| p nom | d max | b1 min | b2 max | h2 max | L max | Q max | q | ||||

| mm | mm | mm | mm | mm | mm | RN | Rg/m | ||||

| 25H | 6.35 | 3.3 | 3.18 | 2.31 | 5.9 | 8.8 | 5.2 | 0.17 | |||

| 219H | 7.774 | 4.59 | 5 | 4.59 | 7.4 | 11.5 | 9.8 | 13/1.03 | |||

| 270H | 8.5 | 5 | 4.75 | 3.28 | 8.2 | 13.1 | 9.8 | 0.42 | |||

EST04CF-76.353.45.22.416.72.8l0.88.29.10.24EST04CF-76.354.57.252.416.72.8l0.810.311.80.312

| Strengthen silent chain | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| RITSUKA | Pitch | Number of plates | Chain width | Pin diameter | Plate depth | Distance from hole center to tooth top | Plate thickness | Pin length max | Tensile strength | weight per meter | |

| Chain No. | |||||||||||

| P | n | b1 min | D2 min | h2 | h2 | t | T | L max | Q max | q | |

| mm | mm | mm | mm | mm | mm | mm | mm | mm | RN | RN | |

| EST04CF-5 | 6.35 | 2.3 | 3.15 | 2.41 | 6.7 | 2.8 | l | 0.8 | 6.1 | 5.2 | 0.165 |