Raw Material

We owe our superiority to the SGS approved Factories where products derive their perfection using innumerable quality parameters. We use minimum BOP (Bought out Parts) to have a complete control of quality.

| Parameter |

Details |

RITSUKA |

Chinese Product |

RITSUKA Advantage |

| BOP |

Base |

Outsourced |

Outsourced |

Since these parts require large infrastructure. All the OEM’s also buy these parts from outsourced factory. |

| Winding |

0.8 MM Copper |

0.75 MM Copper |

Required current generation |

| Filament |

Inhouse |

Outsourced |

Ensure quality standardization |

| Raw material |

Glass |

Quartz |

Normal quality glass |

Better lumen depreciation |

| Filament |

Tungsten |

Substandard tungsten |

High longevity and maximum light. |

| Inside Gas |

Xenon |

Neon |

High longevity and more lumen |

| Lead in wire |

High grade of Copper |

Substandard copper |

High grade copper/appropriate length ensure no leakage |

| Base |

Steel/Iron |

Iron |

Material as per customer requirement |

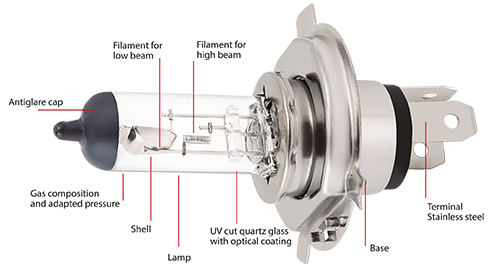

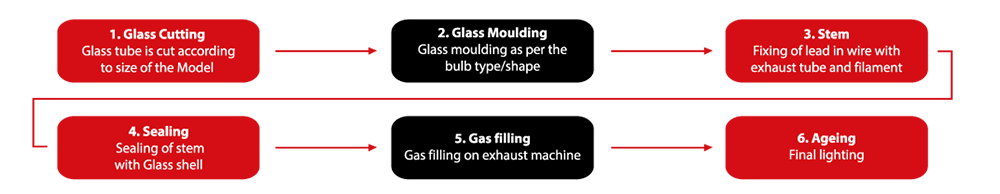

Manufacturing

Our manufacturing facilities are what give us edge over other Chinese products. With fully automated line with minimal manual intervention, we are the top manufacturers of bulbs.

| Parameter |

Details |

RITSUKA |

Chinese Product |

RITSUKA Advantage |

| Manufacturing Process |

Glass cutting |

In-house |

Outsourced |

High quality cutting to avoid chip off. This ensures high longevity |

| Copper winding |

Electrical programmed machine |

Manual hand operation |

Machine will maintain same winding in every pcs, which ensure correct current generation |

| Shell manufacturing |

In-house |

Outsourced |

Inhouse manufacturing ensures better quality control on produced parts |

| Stem manufacturing |

In-house |

Outsourced |

Inhouse manufacturing ensures better quality control on produced parts |

| Bulb sealing |

In-house |

Outsourced |

Inhouse manufacturing ensures better quality control on produced parts |

| Glare Coating |

Inhouse automatic coating machine |

With or without glare coating |

Better quality glare coating ensures proper light focus. |

| Gas filling |

In-house |

In-house |

Inhouse manufacturing ensures better quality control on produced parts |

Testing

Each of our finely manufactured bulbs are tested in our in-house quality lab, which is equipped with international level of testing mechanism like humidity test, life test etc. Apart from in-house checks, we also conduct timely testing of the bulb quality from the external agency. This leads to zero defects and makes our bulb fare highest in quality. We conduct 100% inspection of the raw material before processing them on production floor, and same level of rigorous check takes place while production also. Each bulb is quality tested by the engineers before going for final packing.

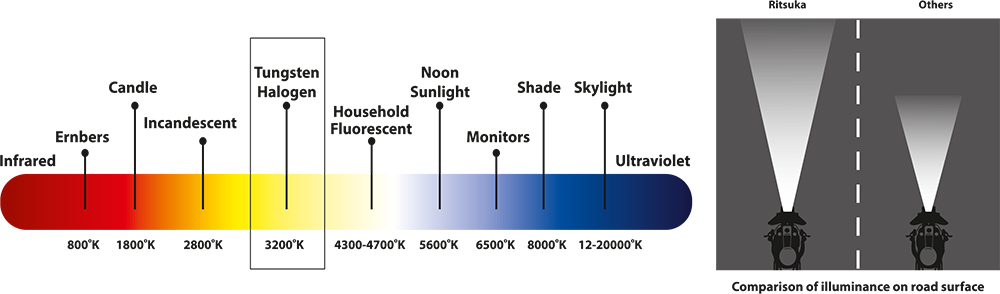

Photometry

Photometric globe is used to check all the electrical parameters of the bulb such as voltage, wattage, current, lumens and color temperature (CCT)

| Parameter |

Details |

RITSUKA |

Chinese Product |

RITSUKA Advantage |

| Testing Standard |

Photometry |

Electrical parameter testing |

No in-house testing, since photometric globe is an expensive equipment |

To check the parameters like lumen, wattage, voltage and current ensuring quality product |

| Photometry Test Report |

| Test Detail: |

Photometry |

Sample type: |

Complete Bulb |

Production Date: |

20.12.2017 |

| Specification: |

H4 12V 35/35W P43T |

Manufacturer: |

Eastman |

Date of Test: |

20.12.2017 |

| Beam Type: |

(High Beam) |

(Low Beam) |

| Parameter: |

Test Volt (V) |

Current (A) |

Wattage (W) |

Lumen (Lm) |

Lm/W |

Color Temp. (K) |

Life (Hrs.) |

Current (A) |

Wattage (W) |

Lumen (Lm) |

Lm/W |

Color Temp. (K) |

Life (Hrs.) |

| Standard: |

13.2 |

– |

33.2~36.8 |

825 (702~948) |

– |

– |

130 |

– |

33.2~36.8 |

525 (447~603) |

– |

– |

150 |

| Sample 1 |

13.2 |

2.764 |

36.5 |

788 |

21.60 |

3199 |

256 |

2.776 |

36.6 |

497 |

13.56 |

3137 |

– |

| Sample 2 |

13.2 |

2.749 |

36.3 |

775 |

21.36 |

3213 |

278 |

2.759 |

36.4 |

485 |

13.32 |

3114 |

– |

| Sample 3 |

13.2 |

2.712 |

35.8 |

763 |

21.31 |

3253 |

296 |

2.766 |

36.5 |

495 |

13.56 |

3152 |

– |

| Sample 4 |

13.2 |

2.725 |

36.0 |

754 |

20.96 |

3231 |

– |

2.772 |

36.6 |

489 |

13.36 |

3151 |

289 |

| Sample 5 |

13.2 |

2.732 |

36.1 |

766 |

21.24 |

3212 |

– |

2.773 |

36.6 |

484 |

13.22 |

3159 |

302 |

| Average: |

13.2 |

2.74 |

36.1 |

769.2 |

21.3 |

3221.6 |

276.7 |

2.77 |

36.6 |

490.0 |

13.4 |

3142.6 |

295.5 |

| Conclusion: |

Passed |

| Checked By: |

|

QA Head: |

|

Luminous flux Φ

Unit: Lumen [lm]

Luminous flux is the term used to represent the quantity of energy of the light emitted per second in all directions.

Light Output ŋ

Unit: Lumen per Watt (lm/W)

The amount of light that falls on a surface is measured in lux. One lux is the light that obtained from a light source of one lumen over an area of one square meter.

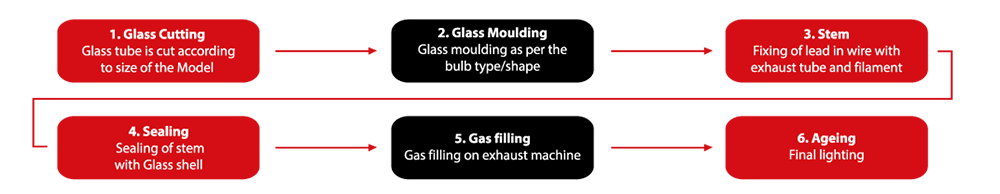

Color Temperature

This is measured in degrees Kelvin that indicates the color of a specific type of light source. (Kelvin is indicated by the unit symbol K.) Color temperatures over 4000K are called cool white colors while lower color temperatures (2700~3000K) are called warm white colors (yellowish white). The higher the temperature of a light source, the greater the portion of blue and lower the proportion of red in the color spectrum.

Life Test

| S.no. |

Parameter |

Details |

RITSUKA |

Chinese Product |

RITSUKA Advantage |

| 1 |

Testing Standard |

Life test |

In house testing |

No life test rack, since it requires infrastructure to manage |

Standard life up to 150 hrs. |

All the bulbs are tested in the life test rack for a long period to check the switching cycle and life expectancy of bulb.

Vibration and shock test

| S.no. |

Parameter |

Details |

RITSUKA |

Chinese Product |

RITSUKA Advantage |

| 1 |

Testing Standard |

Vibration test |

Vibration resistant |

No testing |

Better longevity |

Bulbs are tested on random basis to check the filament strength and vibration resistance of the filament. This test ensures the life expectancy of the bulb.

| S.no. |

Parameter |

Details |

RITSUKA |

Chinese Product |

RITSUKA Advantage |

| 1 |

Testing Standard |

Incoming Quality Inspection |

100% inspection of incoming parts |

No testing |

This ensures that incoming parts are within tolerance limit as per Acceptance Quality Limit (AQL) |

| In process |

100% quality check at different processes |

No quality check, since it requires extra manpower/extra cost |

This ensures that produced parts are within tolerance limit as per AQL |

| Final inspection |

All the bulbs are checked before dispatch to ensure good quality |

No quality check, since it requires extra manpower/extra cost |

Defect free product to customer. |